Services of Rockford Tool

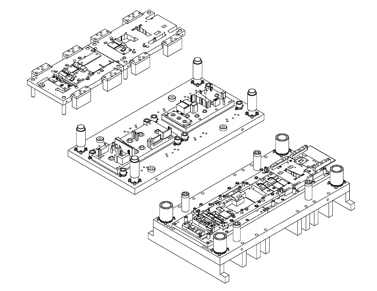

Die Engineering & Construction

- Design using AutoCAD with DIEMAKER and Solid Edge

software for 2D or 3D Drawings - Capable of all aspects from conception, review,

tool build, assembly, debug and production run - In-house designers for quick response to rush jobs

- Properly designed dies that will achieve consistent,

quality parts - Engineering changes

- Reverse engineering and die repair

- Trained die makers and machinists

- Die tryout up to 250 tons

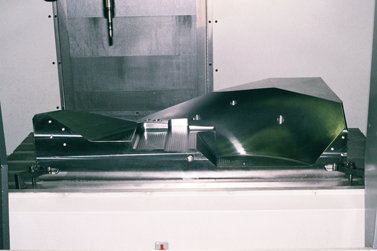

CNC Machining

- 5 late model Vertical machining centers

- CNC Lathe with 17" swing

- Mastercam 3D programming software

- Small or large quantity runs

- Machine Parts to customer specifications

- Machine components for new tooling and repairs

- 3D CNC machining systems and latest software

for absolute accuracy - Table travel to 20" x 50"

- 10,000 RPM spindle

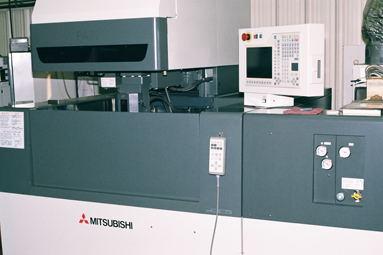

Wire EDM

- 5 late model EDM machines to produce tightly

toleranced parts - DP Technology Espirit programming software

- EDM used for die requirements as well as

customer contract work - High-Speed, automated machines

- Automatic threading for uninterrupted cutting

- Large travel with submerged tanks

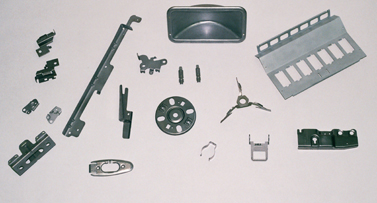

Stamping

- Prototype dies

- Low or high volume runs

- Die repair available as required

- Press sizes from 60-250 tons

- Presses used for die try-out as well as production

- High level of experience running progressive dies